Last updated: 2018-02-06

This page covers getting the MakerGear M2 with V4 Hotend set up on Linux and calibrated well enough to print Benchy.

1 Linux Setup (Ubuntu 16.04)

In order to calibrate the printer, you need to run the MakerGear M2 Quick Start. This is compiled for 32 bit systems, but chances are you’re on a 64 bit system and will need to manually install the 32 bit dependencies.1

sudo dpkg --add-architecture i386

sudo apt update

sudo apt install libc6:i386 libncurses5:i386 libstdc++6:i386 libgtk2.0-0:i386If you try to connect to the printer without setting the correct baud rate, you’ll get a timeout. Below is how to set the correct speed for your TTY device.

sudo stty -F /dev/ttyACM0 115200You should now be able to use the Quick Start as root.

cd M2\ Quick\ Start

chmod +x ./M2\ Quick\ Start

sudo ./M2\ Quick\ StartSetting up Simplify3D is easier. Once it’s installed into /opt, run the launcher script as root.

cd /opt/Simplify3D-4.0.1

sudo ./LaunchScript.shHaving to run everything as root isn’t great, but I didn’t want to spend any more time fiddling with permissions.

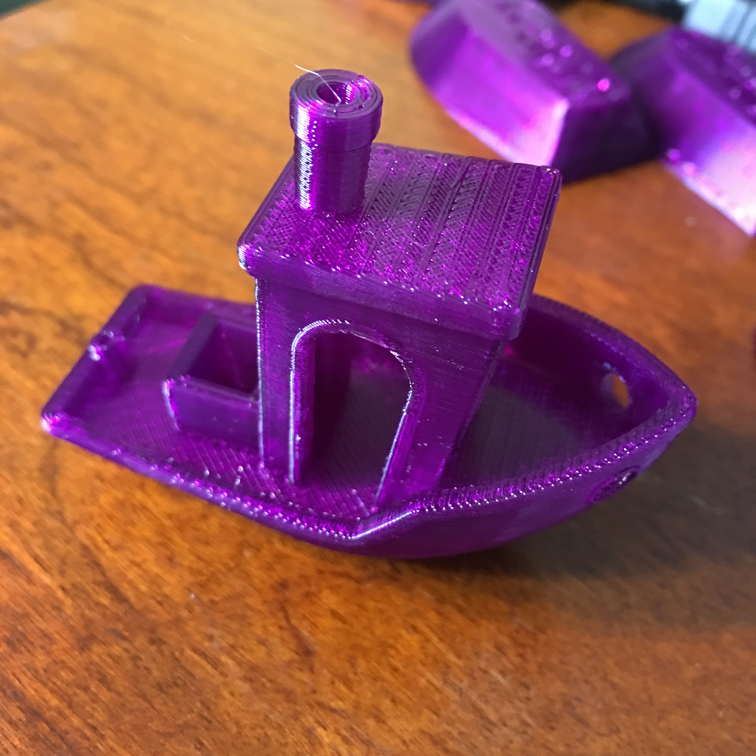

2 Printing Benchy

So you’ve set up your new printer and now you want to print Benchy. My initial Benchy print was an exercise in disappointment. For a printer as expensive as the M2, the result left much to be desired.

The main issue was the overhangs on the outside of the boat. Although the print adhered to the bed without issue, I was getting some rather gnarly curling and warping in the middle and upper layers.

Bridging performance was also terrible. Note the curls of filament in the roof of the cabin.

Finally, both the top and bottom layers had gaps between rows of filament.

I believe this was with stock settings in Simplify3D (MakerGear M2 (24V V4 hotend)) and MakerGear brand PLA.

2.1 Calibration

At a high level, there are 3 main adjustments that made the largest difference.

- Temperature

- Speed

- Orientation

Below I describe how I arrived at the final value of each of these. Remember that each printer, filament, and model is different, so your final settings may be different than mine. This is meant as a starting point, and as an illustration of the thought process one needs to go through to trouble shoot common quality issues. That said, before beginning it’s worth going over this guide from Simplify3D on common printer issues.

Also, before fiddling with settings, re-level the bed with the M2 Quick Start software just to rule that out as a potential issue.

2.1.1 Print Temperature

Ideally, the temperature should be just hot enough to get good extrusion and adhesion. Too low and the filament might not melt fast enough, leading to low extrusion, poor adhesion, and in extreme cases damage to the print head. Too high and the filament won’t cool fast enough, which can lead to curling and other issues.

The MakerGear PLA recommends 220F, but I found I could go as low as 205F and still get good adhesion to the print bed. A breakthrough came when I realized I could set per layer temperatures, meaning I could set the first few layers to 205F, and the following layers to 190 F. Setting the bed temperature to 70F also helped with bed adhesion. Finally, I coated the bed in a couple layers of hairspray (YouTube video describing how).

Below is a picture showing what under extrusion looks like. This print was at 185F. You can see that the top layer of the boat’s deck looks stringy and thin. This is a sign that you’ve decreased the temperature too far.

2.1.2 Print Speed

Print speed can greatly affect the quality of a print. Too high and the head can move before the filament has stuck, and in extreme cases, a very high setting can even cause the motors to skip. Too low and the print will take forever. The idea here is to set the print speed to the highest setting that still gives good quality prints.

By default, both the “Default Print Speed” and the “X/Y Axis Movement” are set way too high. I started by halving the default speed to 40 mm/s2 (from 80 mm/s)

As for the X/Y movement, I set that to 200 mm/s (down from 300 mm/s). I had noticed the motors skipping during other prints, which causes the rest of the print to become misaligned.

Finally, I set the First Layer Speed to 30% to get better bed adhesion. This is the percentage of max speed that’s used when printing the first layer. For good measure, I also set the Outline Underspeed to 50% as it’s the outline layers I was having the warping/curling issue with.

I didn’t put much effort into seeing how high I could go with these settings. If you print large models often, it would be worth your time to gradually increase these setting to see how high they can go.

2.1.3 Print Orientation

If upper layers curls this is usually because it’s not cooling fast enough.3 The slower it cools, the more time it has to warp. This means that positioning tricky areas toward the bed fan can greatly improve performance. In light of this, I oriented the front of Benchy toward the bed fan, to improve cooling on the front and also along the sides.

2.1.4 Bridging

For another print, I set the Unsupported Area Threshold to 20 sq mm. This might have improved the bridging for the roof of the cabin, but I haven’t done extensive testing on this.

2.1.5 Fan Shroud

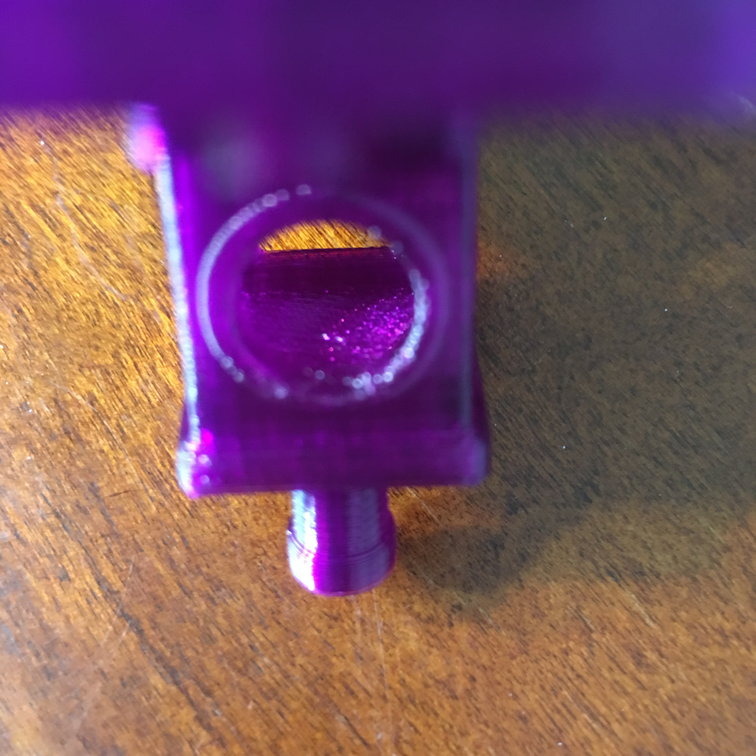

Even with the settings above, I was still having issues with the upper layers of the back left corner curling up. Below is a picture of this.

The problem is that the stock bed fan doesn’t cool the back of the print well enough. To remedy this I printed and installed a fan shroud on the bed fan.

2.1.6 Final Settings and Print

Anything not specified below are defaults:

| Layer Height | 0.2 mm |

| Infill | 20% |

| Layer 1 Temperature | 205F |

| Layer 3+ Temperature | 190F |

| Bed Temperature | 70F |

| Print Speed | 40 mm/s |

| Outline Underspeed | 50% |

| X/Y Axis Movement Speed | 200 mm/s |

| First Layer Speed | 30% |

| Unsupported area threshold | 20 sq mm |

Below you can see there is no more gnarly curling on the sides of the ship.

And the back left corner looks great.

Bridging inside the cabin looks perfect.

Overall I’ve pleased with this print. There are certainly further improvements that could be made, but part of calibrating your printer is knowing when to stop! As with many things, calibration is subject to diminishing marginal returns.

2.1.7 Does It Matter?

Does it matter if you can print a decent Benchy? Not really. Benchy takes much more calibration than most prints. The real test of your printer is “Can it print the objects you want to print?” I, for example, mostly print cases, brackets, and other items in the vein of functional prints. These usually lack fine details and are optimized for ease of printing. Others are more interested in objects like figurines and props, which do have fine detail. The upshot is that the amount of time you should invest into calibration is really a function of what types of objects you’d like to print.

You might be able to get away with only installing libgtk2.0, but I copied this command from the following post↩︎

Most people report their speed in mm/s, so I recommend going into the options menu and setting units to mm/s rather than the default of mm/min↩︎

Weirdly, if the first layer curls, this usually means it cooled too fast. I’m not sure how to reconcile these properties, but my informal tests seem to bear them out.↩︎